Kate: Hi Jonathon. Could you tell us a bit about your job role at Simpsons Malt?

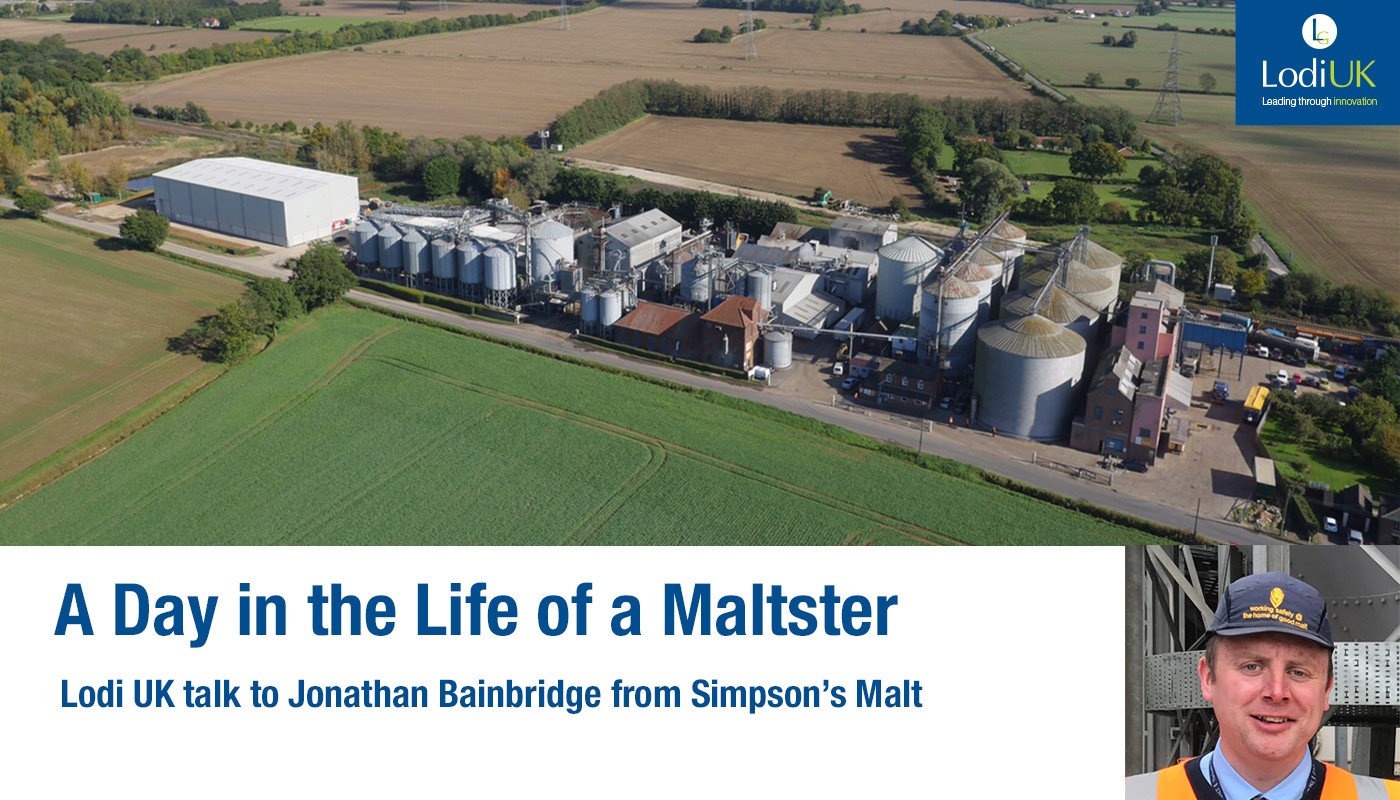

Jonathan: I’m the Production Manager for our barley intake, our Fersfield grain store – which is about ten miles from the maltings – and malt outloading at our Tivetshall St Margaret Maltings in Norfolk.

Kate: What does a standard day in your role look like?

Jonathan: The day will start with a morning meeting with my team to discuss the movement plan for the next 24 hours, followed by a production meeting with management to discuss wider site priorities and planning. Next, I look at what barley requirements we have and work with our planning and transport teams to allocate haulage and storage for barley coming into tip. I work alongside my team to make sure we are on plan for supplying malt to our bagging hall and supplying raw material to our internal customers, the roast house and GKV’s. I will also spend time with our supervisor to work on a plan of allocating storage for barley pre-harvest and also for the annual event itself. No two days are ever the same!

Kate: What are the challenges you face in your job?

Jonathan: When working with barley, you never stop thinking about the weather and what the year ahead will be like. As maltsters, we have to adjust and adapt to the barley that’s available and make sure we are in a position to intake and nurture our stock for production and being in a position to produce quality malt year-on-year. Keeping the flow of production going is always a good challenge, from intake right through to out loading.

Kate: What makes a good harvest for you?

Jonathan: A good harvest is having all the barley come in and tip and we have zero rejections and zero issues on drying and screening. But again, we are in the hands of nature. If farmers have a dry planting season – November time for winter barley and March time for spring barley – and then we have nice drop of rain soon after until the seed has germinated and grown and then get a bit of sun on it, then we know it’s going to be good.

Kate: How do you ensure barley is kept to highest standard in our stores?

Jonathan: After intake, the barley is then dried, screened and then sprayed with K-Obiol pesticide before entering long-term storage. As you can imagine, we don’t want any weevil, dust mites or any variety of bug getting into our barley and eating away at it, so we take precautionary measures by applying a dosage of grain pesticide. Barley is very much a living product even after it has been cut from the field, so we must treat it with respect, protect it and nurture it.

Kate: What is the most rewarding thing about your job?

Kate: It’s true to say that watching every load of malt go out the door to customers all over the world gives me a lot of satisfaction. However, I would say that the most rewarding thing about my job is having a team who are very passionate and knowledgeable and contribute in different ways to the continual improvement of the site. You can’t make good malt out of poor barley.

.png)